Facts About Motorcycle Parts New Zealand Specialists Revealed

Table of ContentsNot known Factual Statements About Motorcycle Parts New Zealand Specialists What Does Motorcycle Parts New Zealand Specialists Do?Motorcycle Parts New Zealand Specialists Can Be Fun For AnyoneMotorcycle Parts New Zealand Specialists Fundamentals ExplainedThe Greatest Guide To Motorcycle Parts New Zealand SpecialistsThe Ultimate Guide To Motorcycle Parts New Zealand SpecialistsWhat Does Motorcycle Parts New Zealand Specialists Do?Some Ideas on Motorcycle Parts New Zealand Specialists You Need To Know

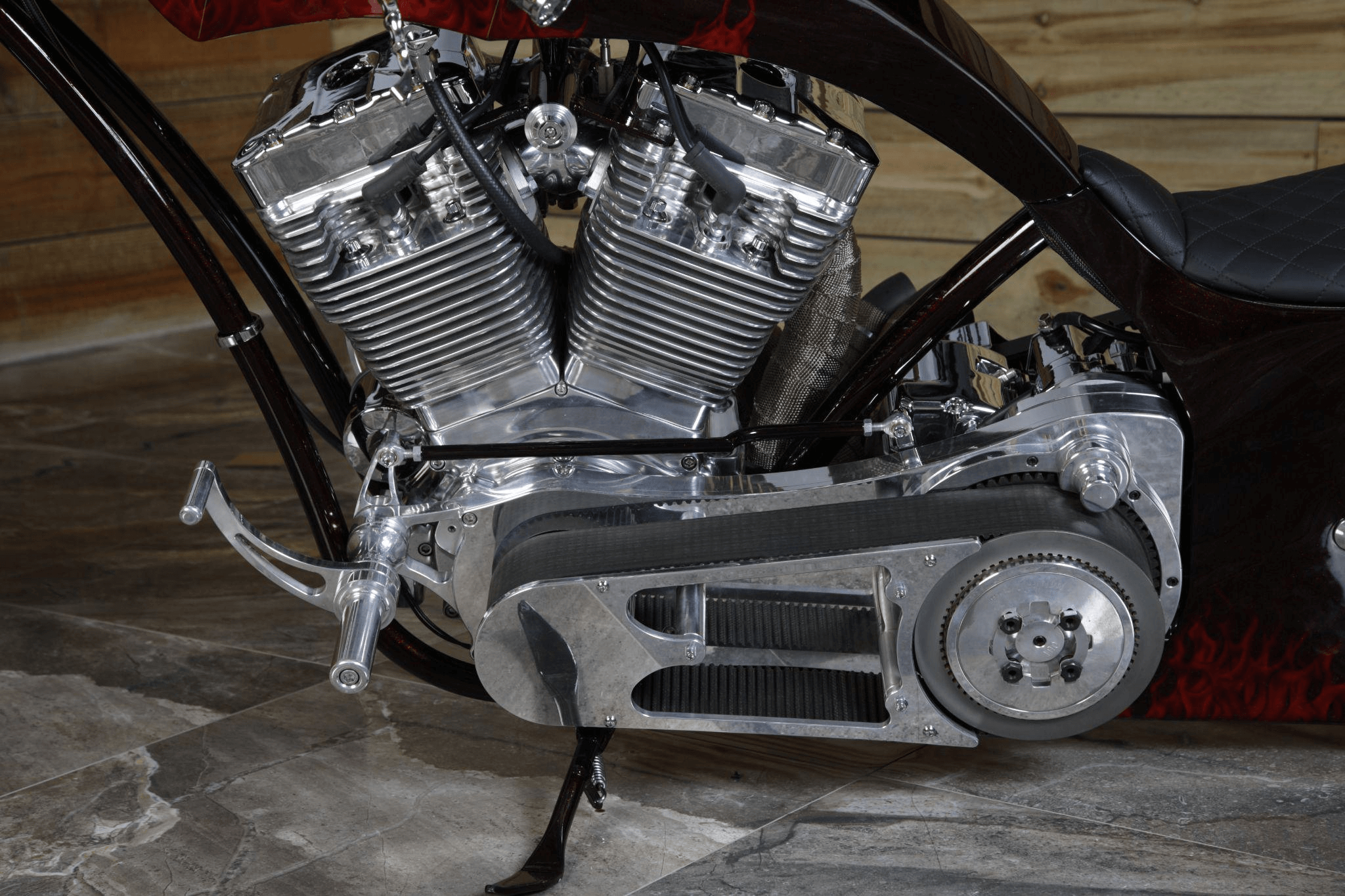

Get to out to one of our experts today.CNC machining modern technology is swiftly ending up being the centerpiece of various production procedures around the globe as a straight result of its several benefits over other techniques. Furthermore, the industries that make motorbikes have actually obtained on board with this trend. The most cutting-edge firms are now developing their engine parts and wheels using machining methods initially created for motorbike parts.

On the various other hand, the results of industry are the main emphasis of this short article. Let's get directly right into it. You may be wondering why we utilize. It is not difficult to fathom the factors that led to this outcome. Since we have your attention let us clarify the reasoning behind this modern-day advancement in the motorbike production sector.

6 Easy Facts About Motorcycle Parts New Zealand Specialists Explained

Additionally, you have complete control over the look of the parts, also down to the minute details. Periodically, motorcyclists might decide to fix up their trip by installing aftermarket components or modifying the bike's transformation. Once more, computer numerical control (CNC) machining is the most functional method. Upgrades might be of any kind of type and design you want.

Getting My Motorcycle Parts New Zealand Specialists To Work

CNC machining may be utilized to make nearly all of a bike's steel and plastic components. To proceed, we'll go over a number of machined parts for motorbikes.

Milling treatments are made use of to get the preferred level of wheel personalization. Another element of the bike that may be individualized is the tires.

Motorcycle Parts New Zealand Specialists Can Be Fun For Everyone

When it concerns a vehicle (or a motorcycle), the most important part is the engine. Numerous people suggest to it as the "heart" of the auto. On the various other hand, the camshaft, the cyndrical tube head, and the pistons tend to be elaborate and need styles with a high level of accuracy.

Usage just high-quality products, however, because these lights are important for the safety and security of motorcyclists and other motorists or people on the roadway, particularly at evening. Bike fronts lights have 3 primary parts: the bulb, or light source, the lens, and the real estate.

Milling procedures with a flawless surface would cause the lenses read this post here having a reflective quality that resembles that of a mirror. The cover, on the various other hand, is not composed of breakable products; rather, it is constructed out of tough polymers that can be machined right into even more detailed patterns.

Things about Motorcycle Parts New Zealand Specialists

They often have fancy geometries with a wide range of minute information. Motorbike makers frequently cast these parts, however only for the production of bespoke parts. Nevertheless, CNC machining is the technique of choice when producing special pieces. Machining on 5 axes in today's world is the methods by which any design form might be understood.

Pick Runsom for your personalized motorbike parts! We have the capability to produce difficult and trendy components making your motorbike matchless.

Here are a few instances of metals frequently utilized in motorbike component machining. Light weight aluminum is the key product made use of by companies specializing in producing custom-made bike components to produce many of these components. In the past, we would certainly build our engines out of actors iron. On the other hand, light weight aluminum is swiftly ending up being the product of choice, partially because of the reality that it is more light-weight.

Zinc describes one more steel that is extremely light in weight and has great machining qualities because of its high mechanical strength. This material might be created right into almost any kind of form and keeps its dimensions well. Even mission-critical elements that require a high level of accuracy might benefit from their use.

What Does Motorcycle Parts New Zealand Specialists Mean?

Another metal that sees heavy usage in the production of CNC-customized elements is magnesium. It is among the lightest metals that are currently available and has outstanding machinability features and stamina proportionate with its reduced weight. Among the drawbacks of magnesium is that its dirt this contact form may easily ignite.

Due to the fact that of its remarkable machinability and weldability, stainless-steel is an alloy that is specifically fit for CNC processes. They have excellent deterioration resistance and a high visual charm. Their most typical use in producing different motorcycle components is bolts, such as screws and screws. Their reduced vulnerability to oxidation and rust makes them perfect for this use.

What Does Motorcycle Parts New Zealand Specialists Mean?

It appears that CNC turning and crushing are the fundamental processes. In addition, it calls for maintaining bars of material, most often plastic or metal, in placement and after that twisting a cutting device to eliminate areas of the material as the product click for source is turned.

These approaches are equally important and generate parts with high precision and constant high quality. The processes aid enhance the general quality of the machined motorcycle parts.

Some Of Motorcycle Parts New Zealand Specialists